Pulp Bale Handling

& Dewiring

DESCRIPTION

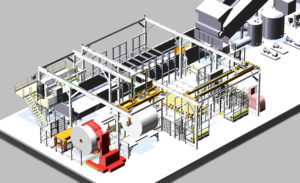

The pulper is the lifeblood of the mill. Heavy-Duty pulper feed conveyors and a flexible controls designs give mill managers the freedom to create hot lanes and advanced recipe handling configurations. Our high-capacity pulp bale handling systems define safety, reliability, and space efficiency.

Automatic Handling’s turnkey solutions flawlessly tackle all the unique challenges inherent to bale handling. We provide fully automatic bale management systems with multi-lane infeeds, traversing robotic destackers, manual and automatic dewiring functionality, integrated magnetic wire detection inspection stations, along with custom buffer charge and pulper feed conveyors. We also offer our mixed recipe management data tracking systems for market pulp bale handling and de-wiring systems.

Applicable Industries

Tissue & Towel

System Highlights

- Uninterupted material flow to your pulper

- Magnetic Inspection for bale wires

- Reduced risk of injury to work force

- Custom engineered for highest possible repulping rates

- Available from pulp drying line or flash drying line

Broke bale introduced to the production line

Broke bale during dewiring

Dewired pulp bale fed through a metal detector

Safety, efficiency, and capacity in bale handling is often a driving factor in replacing older manual dewiring stations. Automatic Handling collaborates with customers to create the perfect pulper feed system for each mill. Whether feeding single bales or multi-stacked bales, our engineers can help you design a safe, flexible, and high capacity de-wiring and handling system that works with your space constraints to deliver the perfect recipe to your pulper, and keeps your team out of harm.

Cut, Coil, and Recycle your bale wires with the comfort of inline magnetic inspection and offline manual inspection at buffer lanes that do not interrupt the continuous flow to your pulper. Whether from a pulp drying line or a flash drying line, our market pulp bale dewiring solutions utilize a similar technology. Wires are cut and coiled, while raw material and pulper are kept clean and wire-free.

Integrated Machine Modules

Depending on your system configuration and bale size, the following machine modules may be integrated:

- Loop Detection at the infeed, with driver-friendly design considerations.

- Multi-stack infeed lanes designed for safety in operation and maintenance.

- Dedicated recipe infeed lanes for species or type-specific recipes (i.e., Hardwood, softwood)

- Automatic single bale dewiring machines for safely removing bale wires

- Pass-through metal detection stations that safeguard against stray debris in the material flow or system

- Robotic bales stacking and destacking transfer carts for a low footprint, high capacity systems

- Heavy-duty buffer chain conveyors designed for efficient service and chain tensioning.

- Manual dewiring stations for handling reject bales while continuing to track bale data in the PLC’s recipe control system.

- Pulp feeder conveyors designed reliability in the most challenging of environments.

Additional BALE Destacking and Dewiring Capabilities

Automating the management of standard pulp bales allows you to reduce risks, improve the safety of your pulp and paper operation while controlling the flow of material through your production environment. Automatic Handling’s broke bale dewiring system can automatically dewire bales of any size on the fly based on compression bail size.

Automatic bale destacker

Automated bale stack cart

Bale stack receiving station