Industries We Automate -

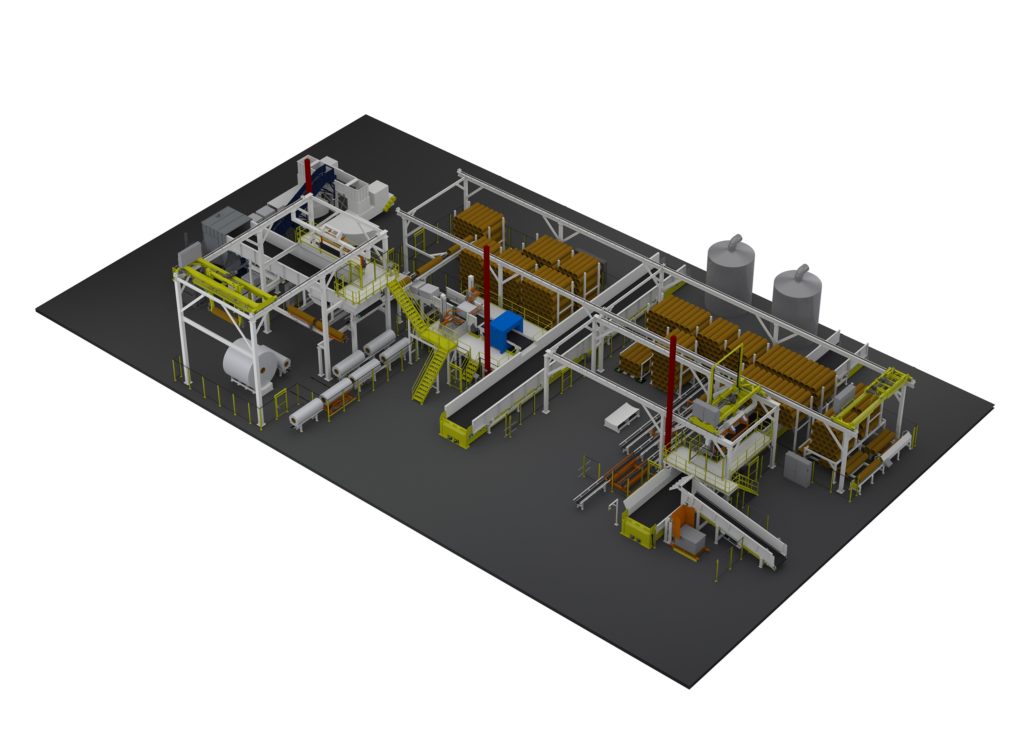

Tissue & Towel Solutions

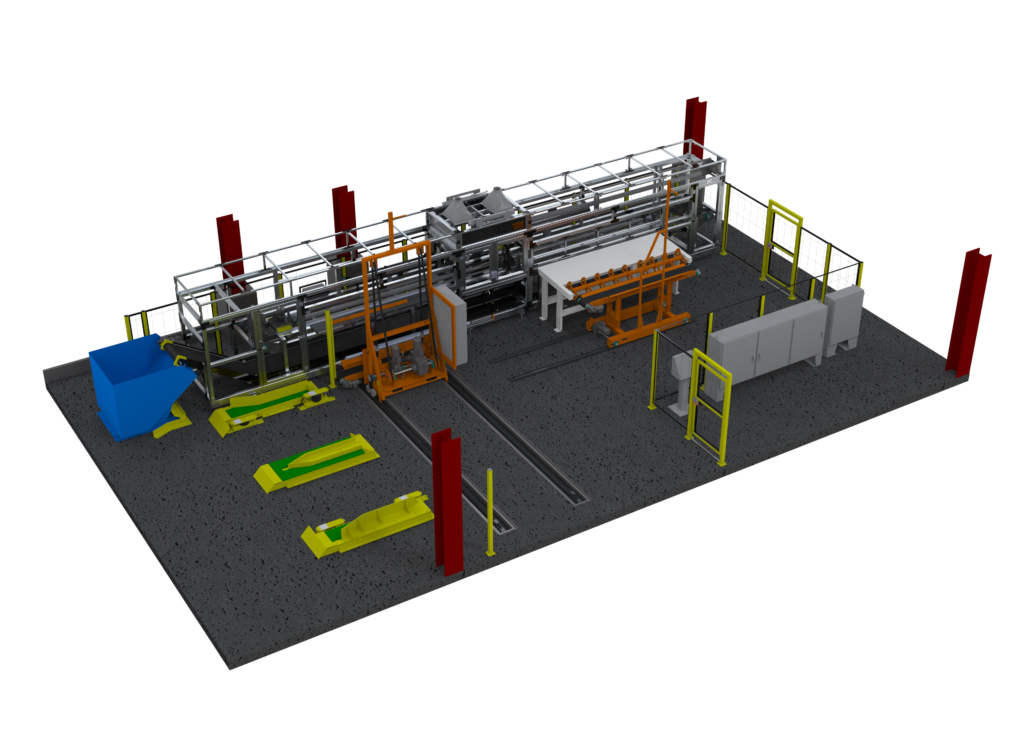

Automatic Handling International, Inc. is a leading provider of automated roll-handling equipment specifically designed for the tissue and towel industry. With over 50 years of experience working with the nation’s largest manufacturers in this sector, our solutions cover all aspects of roll handling, from bale handling and dewiring systems to dry-end roll handling systems and parent roll load and unload systems. We also specialize in core cleaning and broken handling systems, as well as core joining and recycling systems.

Contact us today to discuss your automation needs and how we can help improve your roll-handling operations.

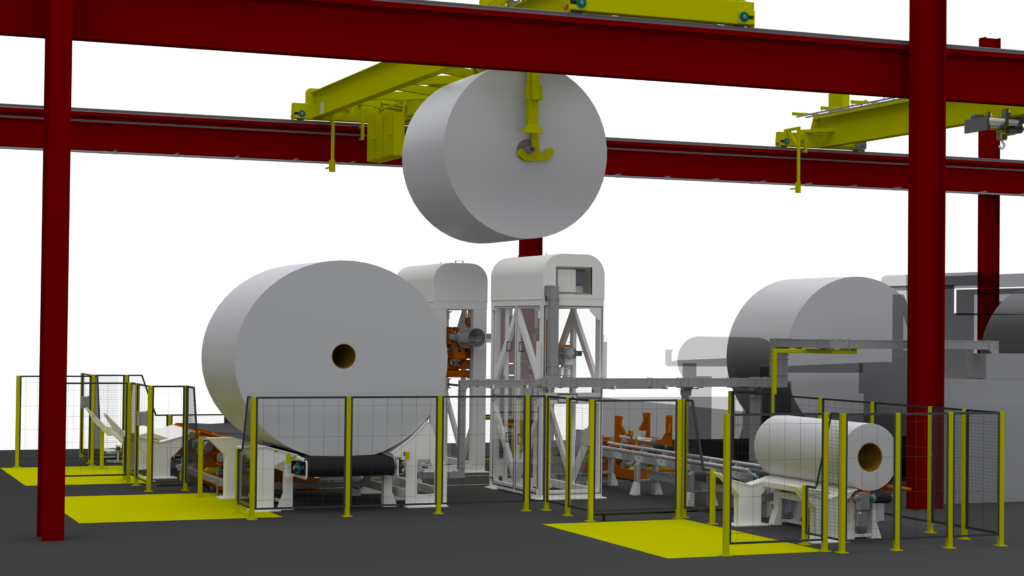

AUTOMATED ROLL HANDLING, ROLL WRAPPING & ROLL PACKAGING

Automatic Handling’s rich history of innovation and problem-solving has made us a leader in the automation of heavy-duty roll handling, roll wrapping, and roll packaging. Our roll handling equipment is designed and built in-house by our team of degreed engineers and highly skilled fabricators, machinists, electricians, and assemblers. We utilize the latest 3D modeling software and scanning technology to ensure a precise design and avoid interferences with existing structures. Every project is assigned a dedicated project manager who is committed to customer satisfaction and on-time product delivery.

Bale Handling & Dewiring Systems

Automatic Handling’s turnkey solutions flawlessly tackle all of the unique challenges inherent to bale handling. We provide fully automatic bale management systems with multiple lane functionality, traversing destackers, and complete recipe management integration with pulpers. We also offer a 100% Wire-Free Guarantee with our automatic de-wiring system to improve safety and reduce downtime.

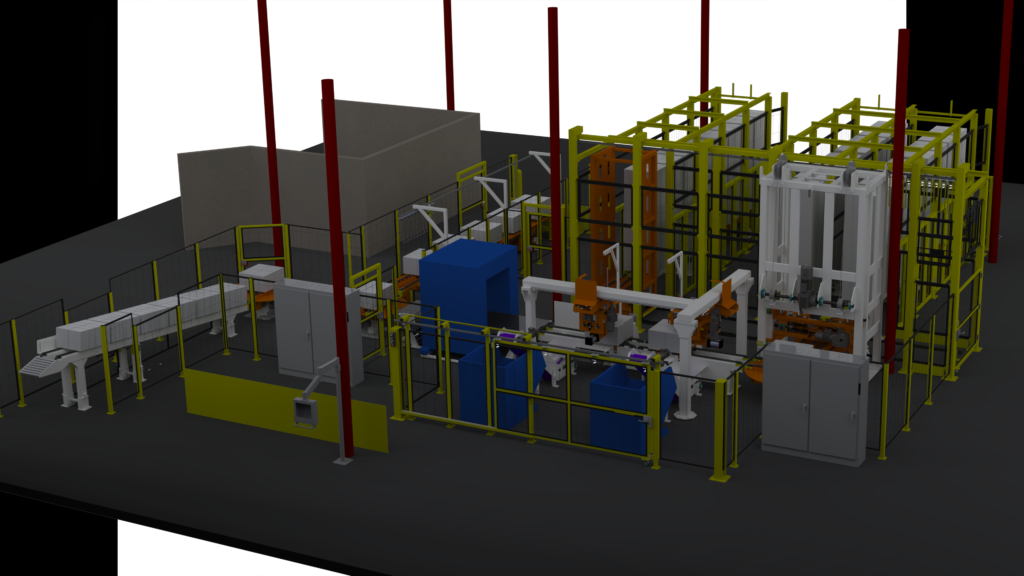

Dry End Roll Handling Systems

We can make automating the dry end of your machine easier than you may think possible. At Automatic Handling, we can outfit existing machines, or design new ones, to include automatic inflate and deflate shaft pullers, label applications, auto spool return, internal core storage, and more to suit your distinct needs.

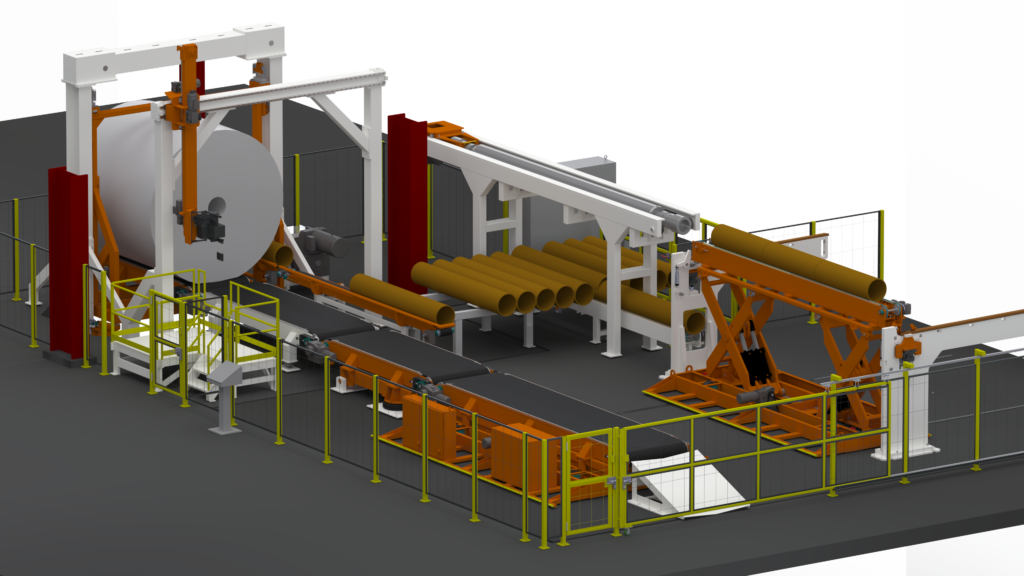

Parent Roll Load & Unload Systems

Our Parent Roll Load & Unload System automates core plug insertion and removal, parent roll loading, and core processing for tissue converting lines. It enhances worker safety, streamlines raw material introduction, and allows for easy removal of reject cores.

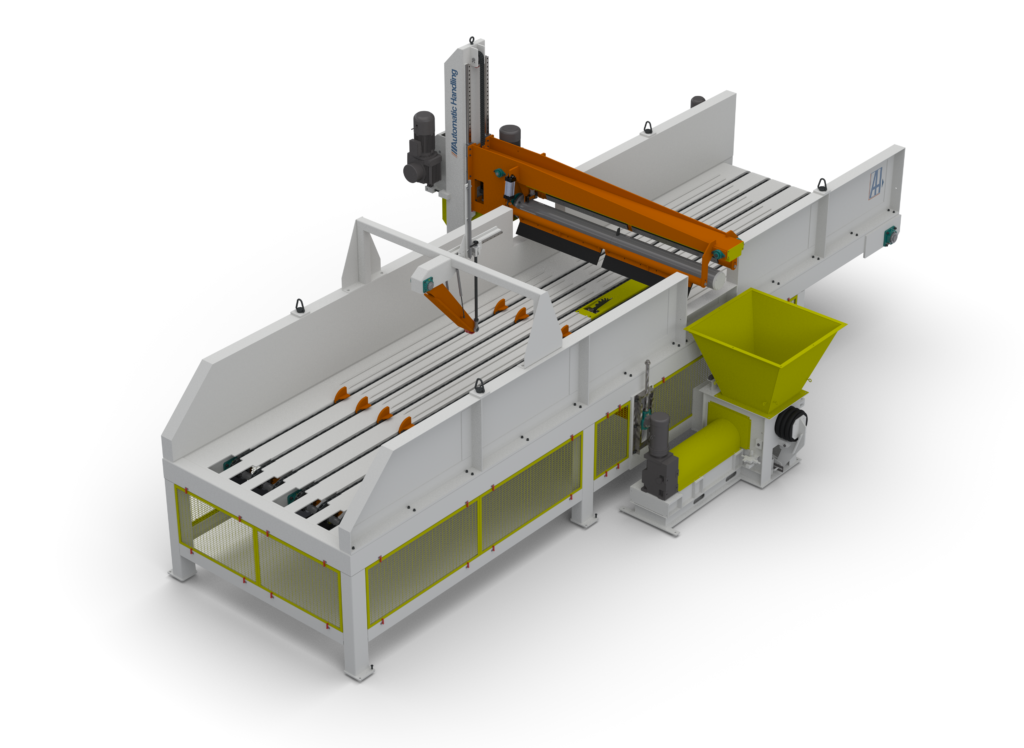

Core Cleaning & Broke Handling Systems

Our extensive line of fully automated core cleaning and broken handling technology includes roll slabbing and broke management, as well as, core cleaning, inspection, and storage. Our systems can slab parent rolls up to 140 inches in diameter, accumulate broken-form pulp, and load cores automatically.

Core Joining Systems

Core Joining System offers cost and eco-friendly benefits. This fully automatic system glues recycled cores into new ones, customized to fit your mill’s needs precisely. By reusing cores of various sizes and grades, paper manufacturers can cut costs and environmental impact significantly.

broke bale dewiring

We specialize in providing advanced solutions for broke bale dewiring. This innovative systems efficiently removes wires or other materials used to secure bales of recycled paper, allowing for seamless breakdown of the bales. This process is fundamental in optimizing the handling and processing of recycled paper materials, reflecting our commitment to enhancing operational efficiency and sustainability in recycling operations.

At Automatic Handling International, Inc. we are committed to providing our customers with innovative and reliable solutions for their tissue and towel roll handling needs. Contact us today to discuss how we can help improve your operations and increase productivity.

Need Help With A Different Industry?

Our team at Automatic Handling International, Inc. excels in providing specialty solutions for your unique manufacturing needs. With our extensive experience in roll handling, roll wrapping, and roll packaging, we are well-equipped to tackle even the most specialized projects.

Whether you require customized equipment or have specific automation requirements, we are here to help. Our team of experts will work closely with you to understand your unique challenges and develop tailored solutions that meet your exact specifications.

With our state-of-the-art facilities, including over 140,000 sq ft of production space and 30′ high assembly bays, we can manufacture anything you need. No matter how complex or specialized your project may be, we have the expertise and resources to deliver high-quality solutions that streamline your manufacturing processes.

Contact us today to discuss your specialty manufacturing needs, and let us provide you with innovative and efficient solutions that will exceed your expectations.