Imagine a world where your production line moves as smoothly and efficiently as a well-oiled machine. That’s the reality Automatic Handling International creates with our cutting-edge automated handling systems. These systems are not just about keeping up with the competition — they’re about setting the pace, enhancing safety, and dramatically increasing efficiency across various industries. Ready to transform your operations? Contact us today to see how automated systems can revolutionize your workplace.

The Role of Automated Systems

Automated handling systems have revolutionized the roll handling and material handling equipment sectors, providing businesses with a more efficient and streamlined approach to their operations. These systems are specifically designed to minimize manual labor and reduce errors, ultimately boosting production efficiency. By automating routine tasks like core joining, wrapping, and core cleaning, businesses can free up their human resources to focus on more critical and value-added activities.

This strategic shift not only optimizes operations but also enhances employee satisfaction by eliminating repetitive and physically demanding tasks from their workload. With the implementation of automated handling systems, businesses can achieve higher levels of efficiency while also improving the well-being of their employees.

Protecting Your Most Valuable Asset

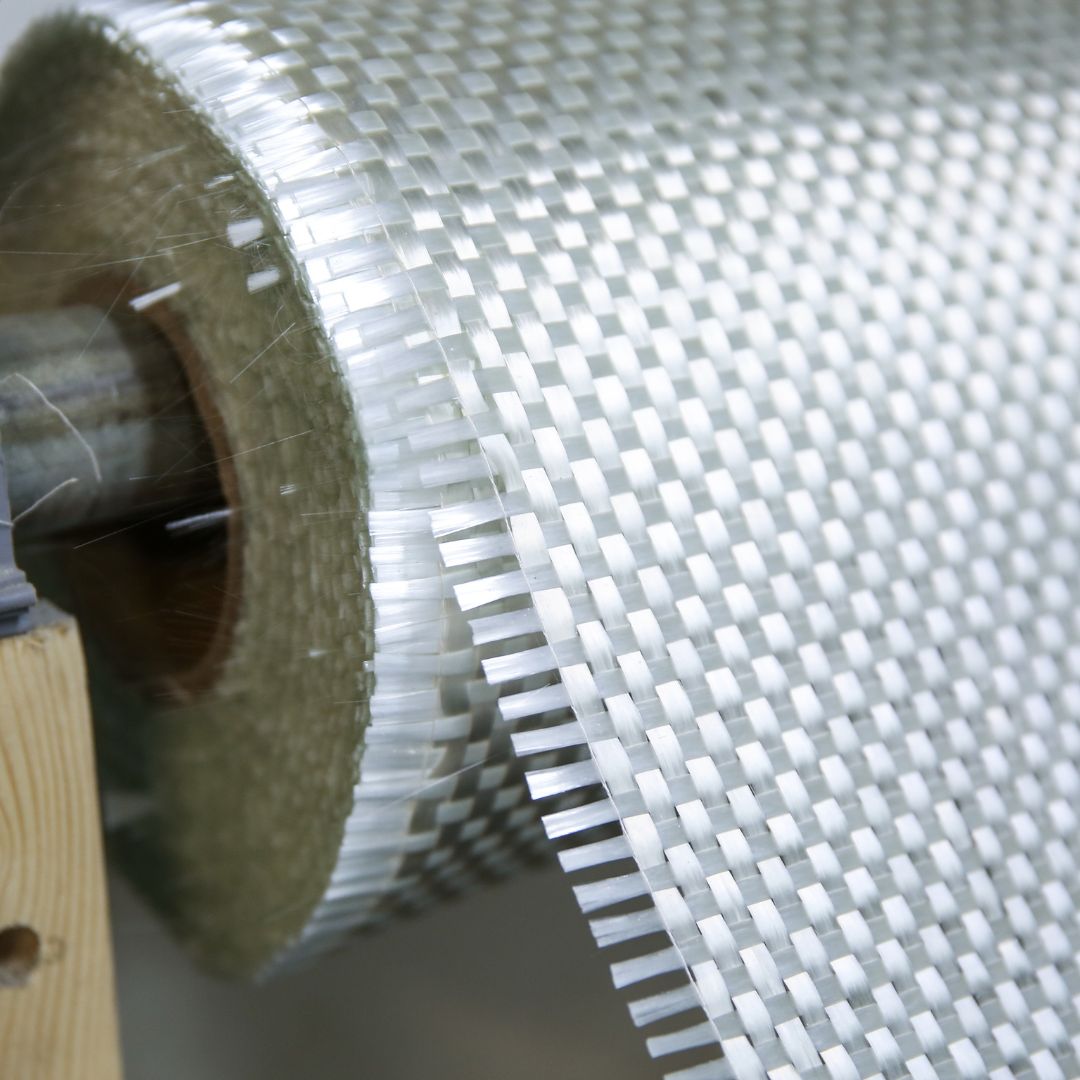

When it comes to material handling, it’s no secret that every industry faces its own set of hurdles. From paper to fiberglass to tissue, each material comes with its own unique challenges. That’s why our bespoke solutions are tailored to cater to these specific needs. Our team understands the importance of efficiency and precision when handling different materials, and our solutions are designed to help you overcome any obstacles you may face. With our expertise and specialized approach, we are confident in our ability to provide top-notch material handling solutions for your industry.

Adapting to Market Demands

In today’s fast-paced market, adaptability is crucial for businesses to stay competitive. That’s where our automated handling systems come in. These systems are specifically designed to be flexible and can easily adapt to various operational scales and needs. Whether your business experiences seasonal spikes or needs to scale operations up or down, these systems can be easily programmed and reconfigured to meet changing demands without the need for significant overhauls. This allows your business to remain responsive and competitive in the ever-changing market. With an automated handling system in place, you can ensure that your business is equipped to handle any challenges that come your way.

Cost Efficiency and Sustainability

Investing in automated handling systems may seem like a big expense at first, but the long-term benefits are undeniable. The savings in labor costs, decreased risk of injury, and increased productivity all contribute to a strong return on investment. What’s more, these systems often utilize cutting-edge technology, resulting in lower energy consumption and less material waste.

This not only aligns with the growing demand for sustainable business practices, but it also helps to further reduce costs in the long run. With all these advantages in mind, it’s clear that the initial investment in automated handling systems is well worth it.

As we look to the future, the importance of integrating automated handling systems into manufacturing and production processes cannot be overstated. At Automatic Handling International, we’re not just providing equipment — we’re building a partnership that helps you innovate and stay ahead of the curve. Are you ready to take the next step in operational excellence? Contact us today to find out how we can help you transition to a more automated, efficient, and safe production environment.